In today’s competitive manufacturing landscape, effective maintenance processes are the backbone of operational excellence. Unplanned equipment failures, inefficient workflows, and prolonged downtime can cripple productivity and erode profit margins. Operations managers face mounting pressure to keep production lines running smoothly while managing costs and maintaining quality standards. Traditional maintenance approaches often fall short, relying on reactive strategies that address problems only after they occur. This outdated methodology leads to cascading issues: emergency repairs, rushed decisions, and frustrated teams scrambling to restore normal operations.

Moore Automated offers a transformative solution to these persistent challenges. By leveraging advanced automation technology and intelligent maintenance management, it empowers manufacturing facilities to shift from reactive firefighting to proactive system optimization. Whether you’re struggling with equipment reliability, maintenance scheduling inefficiencies, or lack of real-time visibility into your operations, Moore Automated provides the tools and insights needed to revolutionize how your facility approaches maintenance, ensuring maximum uptime and operational efficiency.

Understanding the Challenges

Operations managers in manufacturing environments grapple with multiple interconnected obstacles that threaten productivity. Equipment breakdowns arrive without warning, forcing teams into costly emergency response mode. Maintenance teams often lack clear visibility into asset health, making it impossible to predict failures before they happen. Paper-based work orders and fragmented communication systems create confusion about task priorities and completion status. Skilled technicians waste valuable time searching for documentation, tracking down parts, or waiting for approvals instead of performing actual repairs. Budget constraints add another layer of complexity, as managers must balance the need for preventive maintenance against immediate production demands. These challenges compound over time, creating a cycle where reactive maintenance becomes the norm, equipment degradation accelerates, and operational costs spiral upward while overall equipment effectiveness steadily declines.

Introduction to Moore Automated

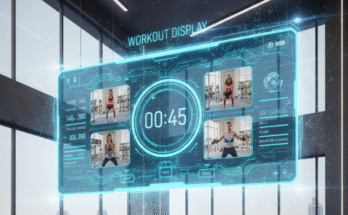

Moore Automated represents a comprehensive maintenance management platform designed specifically for modern manufacturing environments. At its core, the system combines predictive analytics, automated workflow management, and real-time monitoring capabilities to transform how facilities handle equipment maintenance. The platform centralizes all maintenance data into a single accessible dashboard, giving operations managers complete visibility into asset performance, work order status, and resource allocation. Key features include automated scheduling that intelligently prioritizes tasks based on equipment criticality and operational impact, mobile accessibility that empowers technicians to access information and update work orders from anywhere on the factory floor, and integrated inventory management that ensures critical spare parts are always available when needed. The system’s intuitive interface requires minimal training, allowing teams to adopt the technology quickly without disrupting ongoing operations. By connecting maintenance activities directly to production goals, Moore Automated bridges the gap between reactive problem-solving and strategic asset management, enabling facilities to optimize performance systematically.

Improving System Maintenance

Moore Automated fundamentally transforms maintenance workflows through intelligent automation that eliminates inefficiencies at every stage. The platform begins by establishing baseline performance metrics for each asset, continuously monitoring operating parameters like temperature, vibration, and cycle times to detect subtle deviations that signal developing problems. When the system identifies anomalies, it automatically generates work orders and assigns them to qualified technicians based on skill sets and current workload, eliminating the delays inherent in manual scheduling processes. Technicians receive detailed diagnostic information directly on their mobile devices, including equipment history, recommended procedures, and parts requirements, enabling them to arrive prepared with the right tools and components. The system tracks work order progress in real time, automatically updating stakeholders and triggering escalations when tasks exceed expected completion times. Preventive maintenance schedules adapt dynamically based on actual equipment usage and condition rather than arbitrary calendar intervals, ensuring resources focus where they deliver maximum impact. Maintenance teams can document repairs with photos, notes, and time stamps directly within the platform, building a comprehensive knowledge base that improves future troubleshooting efficiency. This systematic approach replaces guesswork with data-driven decision-making, transforming maintenance from a cost center into a strategic advantage that consistently delivers measurable improvements in equipment reliability and operational performance.

Reducing Downtime

Downtime represents one of the most costly challenges in manufacturing, and Moore Automated addresses this critical issue through rapid response capabilities and predictive intervention strategies. The platform’s real-time monitoring system identifies potential failures before they escalate into full breakdowns, allowing maintenance teams to schedule repairs during planned production gaps rather than experiencing unexpected shutdowns. When equipment does fail, the system immediately alerts relevant personnel with comprehensive diagnostic data, eliminating the time typically lost to problem identification and troubleshooting. Technicians access step-by-step repair guidance and parts availability information instantly, reducing mean time to repair significantly. The platform’s historical data analysis reveals patterns in equipment behavior, enabling managers to address root causes rather than repeatedly fixing symptoms. Emergency response protocols are built directly into the workflow, automatically escalating critical issues to senior technicians or external specialists when needed. By maintaining detailed records of past incidents and solutions, the system accelerates resolution times for recurring problems. This multi-layered approach to downtime reduction transforms how facilities respond to disruptions, shifting from extended recovery periods to swift, coordinated interventions that restore operations quickly and prevent future occurrences through continuous improvement of maintenance strategies.

Case Studies and Testimonials

Manufacturing facilities across diverse industries have experienced transformative results after implementing Moore Automated. A mid-sized automotive parts manufacturer reduced unplanned downtime by 47% within six months, directly attributing the improvement to predictive maintenance alerts that caught bearing failures and hydraulic issues before they caused line stoppages. Their operations manager noted that technicians now complete repairs 30% faster thanks to mobile access to equipment documentation and parts inventory. A food processing plant struggling with compliance documentation found the platform’s automated record-keeping invaluable during regulatory audits, while simultaneously cutting maintenance labor costs by optimizing technician schedules and eliminating redundant inspections. An electronics assembly facility reported that equipment lifespan increased measurably as the system’s condition-based maintenance approach replaced their previous time-based schedule, preventing both over-maintenance and neglect. These success stories demonstrate how Moore Automated delivers tangible operational improvements regardless of facility size or production type, consistently helping organizations achieve reliability targets they previously considered unattainable.

Integration with Existing Systems

Moore Automated seamlessly connects with established manufacturing infrastructure through flexible integration capabilities that protect existing technology investments. The platform supports standard industrial protocols and APIs, enabling direct communication with SCADA systems, ERP software, and legacy equipment monitoring tools without requiring costly replacements. For facilities utilizing programmable logic controllers (PLCs) to manage production equipment, the system interfaces directly with these control systems to gather real-time operational data and trigger maintenance workflows based on actual machine performance. Pre-built connectors facilitate rapid deployment with popular enterprise systems, while custom integration options accommodate unique facility requirements. Data flows bidirectionally, allowing Moore Automated to pull operational information from existing sources while pushing maintenance insights back into enterprise dashboards. This interoperability ensures maintenance activities align with broader production planning and financial management processes, creating unified visibility across departments without disrupting established workflows or requiring extensive IT resources for implementation.

Security and Reliability

Moore Automated prioritizes data protection and system stability through enterprise-grade security architecture built specifically for manufacturing environments. The platform employs multi-layered encryption for data transmission and storage, ensuring sensitive operational information remains protected from unauthorized access. Role-based access controls allow administrators to define precise permissions for different user groups, preventing accidental data modification while maintaining appropriate visibility across teams. Regular automated backups safeguard critical maintenance records against data loss, with redundant storage systems ensuring information availability even during system failures. The platform undergoes continuous security audits and updates to address emerging threats without disrupting daily operations. Reliability features include 99.9% uptime guarantees supported by redundant server infrastructure and failover protocols that maintain system availability during maintenance windows or unexpected outages. Cloud-based deployment options eliminate the burden of on-site server management while providing scalable performance that adapts to facility growth. These robust security and reliability measures give operations managers confidence that their maintenance management system will perform consistently while protecting valuable operational data from both external threats and internal system failures.

Pricing and Support

Moore Automated offers flexible pricing structures tailored to facility size and operational complexity, ensuring accessibility for organizations at different growth stages. Subscription models scale based on the number of assets monitored and users accessing the platform, allowing facilities to expand capabilities as needs evolve without prohibitive upfront investments. The company provides comprehensive onboarding support including system configuration, data migration assistance, and personalized training sessions that accelerate team adoption. Ongoing technical support is available through multiple channels including phone, email, and live chat, with response times prioritized based on issue severity. Regular platform updates and feature enhancements are included in subscription plans, ensuring facilities benefit from continuous improvement without additional costs. Dedicated account managers work with operations teams to optimize system utilization and identify opportunities for enhanced performance as operational requirements change over time.

Transform Your Maintenance Operations Today

Moore Automated delivers a comprehensive solution that addresses the critical maintenance challenges facing modern manufacturing facilities. By replacing reactive approaches with intelligent automation, predictive analytics, and real-time monitoring, the platform empowers operations managers to achieve unprecedented levels of equipment reliability and operational efficiency. Facilities implementing this system consistently experience dramatic reductions in unplanned downtime, faster repair cycles, optimized resource allocation, and measurable cost savings. The platform’s seamless integration capabilities, robust security features, and flexible pricing structures make it accessible to organizations of all sizes seeking to transform their maintenance operations. Rather than continuing to struggle with outdated processes that drain resources and limit productivity, forward-thinking manufacturers are embracing Moore Automated as their strategic partner in achieving operational excellence. The question isn’t whether your facility can afford to implement advanced maintenance management—it’s whether you can afford to continue without it. Take the decisive step toward revolutionizing your maintenance processes and unlocking your facility’s full production potential with Moore Automated.