As inline flexo printing machines mark a triumph for label businesses, it underscored the need for efficiency and immediate quality brand output in the upgrading spaces of packaging technology. Furthermore, these types of machinery marked a leap towards meeting consumer needs in bulk without gambling on brilliance. This also emphasizes the need for reliable return on investment and flexibility in scope for those aiming for maximum output. Adding this technology inline does make the investment justify the-di-phrase ‘maximize profit and minimize expenses’.

Labeling does rely on the right technology. And so does the client of plastic bag manufacturers who align their business with shifts in machinery technology. Automated inline flexo labeling specifically meets and enhances high speed and volume output for seamless production lines. With regard to bag manufacturing machines, improvement in labeling determines changeovers durations.

Because this article aims to focus on how inline flexo printing machines serve as tools to escalate targets in vertical scaling of finesse as well as agility in completing plastic bag making machine boxed units, we also need to take into account supporting literature on reasoning for these shifts by the plastic bag making machine manufacturers.

The Fundamentals of Inline Flexo Printing Machines

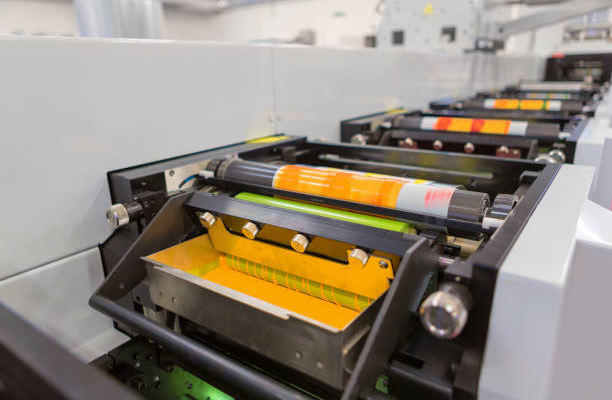

Flexo inline printing is able to print steadily on flexible foils, papers, and films. They’re employed in bag making, labeling, and other forms of flexible packaging. Furthermore, flexo printing differs from other forms of printing in its continuous flow of production as multiple printing stations are lined one after the other which allows coloration on the substrate in single flow.

This means time and material wastage is minimized in packaging lines – a perk for plastic bag making machine manufacturers. In this sense, the ability of the in-line flexo printing machines to print high speed labels at greater speeds makes them indispensable in the production process. By reducing downtime, the technology assists manufacturers in managing the increasing demand without lowering the standard quality.

Other than that, flexo printing machines also include sophisticated features like automatic register control, precise ink metering, and fast drying systems. These features achieve sharp details and perfect color congruity, enhancing the appearance and functionality of the labels, which is vital for businesses striving to elevate their brand identity.

How KETE Is Leading Innovation in Plastic Bag Machine Technology

KETE is one of the leaders in the industry having made great strides in innovativeness by developing plastic bag machines with superb efficiency and quality. The company boasts of uncompromising control, user friendly workflows, and complex speed production algorithms that ensure optimal outputs.

KETE’s energy efficient plastic bag machines help lower the operational costs of businesses while keeping the bar high in terms of production. With cutting and sealing precision technology, the machines are tailored to reduce waste which is critical in the production of quality bags by eliminating surplus materials. KETE’s machines also bolster energy efficiency which harnesses sustainability targets, allowing businesses greater appeal for those venturing to go green.

While KETE focuses on production efficiency, he also takes into account the sustainability of the environment. The machines are thoughtfully designed to lower energy and material waste, making operations greener for businesses. KETE responds to the growing demand from consumers for environmentally sound packaging by embedding sustainable practices into his designs, allowing businesses to meet eco-conscious consumer needs with far greater ease.

The Role of Slitter Rewinder Machines in Label Production

KETE specializes in advanced label finishing solutions. Label slitting and rewinders, KETE’s specialized machines, integrate cutting and drilling with packaging processes to optimize efficiency throughout the entire label production cycle. However, advanced multilayer micromachining, laser technologies, multi-head spinning, and other highly developed technologic capabilities differentiate KETE from its competition.

KETE incorporates advanced technology to reduce both material and time wastage during each production cycle. Slitting and rewinder systems equipped with KETE’s advanced technology enable businesses to improve bottom lines through waste reduction while efficiently switching between job tasks. Complete integration of slitting, drilling, and packaging optimizes multitasking efficiency across multiple production phases.

KETE guarantees that all their endpoints meet mold standards set by other industry innovators. Automated micromachining with multi-axis scaffolds, as well as distributed rotating base thin copters, ensure high speed multi-axis rotating adjustments. KETE’s cutting-edge machinery can also handle meeting increased demands without compromising precision, accuracy, or speed when completing repetitive tasks.

The Future of Plastic Bag Machines and Packaging Solutions

Technological advances of plastic bag equipment are synchronized to the changes in the packaging industry. With the continuous improvements on automation, robotics, and green initiatives, the outlook for plastic bag manufacturing is looking optimistic. Innovative companies like KETE are actively shifting this outlook with their modern solutions tailored to sophisticated packaging problems.

The increase in demand for sustainable forms of packaging is prompting the creation of greener materials and production methods. Accordingly, KETE is developing equipment that works with compostable films which lessens the ecological burden without sacrificing business needs. On top of that, KETE is focused on enhancing the effectiveness of their slitter rewinders to optimize material usage and reduce wastage.

In the context of changing consumer criteria and sustainable business practices, side weld plastic bag machines will remain crucial within the entire packaging sphere. KETE’s continuing focus on every aspect of business – innovation, operational efficiency, and environmental sustainability – allows them to stay relevant in a fast-paced marketplace while remaining the partner of choice.

Conclusion

For companies trying to optimize their label printing operations, inline flexo printing machines are nothing short of a game changer. Because of improvements in print quality, speed, and overall efficiency, these machines give manufacturers a leg up in the packaging industry. In the case of plastic bag making machine manufacturers, the addition of inline flexo printing machines can optimize production lines, lower costs, and maintain the high standard quality of their products needed in today’s commerce.

With the current market trends, businesses are looking for economical, time-efficient, and thorough packaging techniques. This assures that the use of inline flexo printing machines as an investment will pay off in the long-run. Your business can also book big wins when equipped with the right technologies inline flexo printing machines including high quality label attainment plastic bag production machines to fulfill the always changing demands of consumers.