In heavy manufacturing, unplanned equipment downtime stands as one of the most significant profit killers. Often, the root cause of these costly interruptions lies in the failure of industrial gear transmission systems. A single unexpected breakdown can lead to exorbitant repair bills and, more critically, massive production losses. The core issue frequently isn’t the quality of the gear itself but a fundamental mismatch between the gear type and the demanding application scenarios — such as shock loads, extreme temperatures, and continuous operation — coupled with an oversight of critical design precision and material science. The traditional reactive model of “run-to-failure” is no longer sufficient for modern, high-efficiency production.

This article provides a strategic, preventive framework for gear selection and management, guiding you to move beyond simple part replacement and adopt a systems-engineering approach to reliability. To build this strategy, we must first deeply understand the inherent characteristics of different gear types and their ideal applications.

What Are the Fundamental Types of Industrial Gears and Where Do They Excel?

Selecting the right gear is the first and most critical step in building a reliable system. It’s not about finding the “best” gear, but the most appropriate one for the specific task.

1. Spur Gears: The Go-To for Simplicity and Efficiency

Spur gears are the most common type, characterized by teeth that are straight and parallel to the gear’s axis. Their primary advantage is high transmission efficiency due to the parallel teeth meshing uniformly. They are relatively simple to manufacture and are ideal for applications requiring moderate load and speed, such as conveyor systems and simple speed reducers. However, their design can generate significant noise and vibration at higher speeds, as teeth engage in a single, impactful collision.

2. Helical Gears: Engineered for High Load and Smooth Operation

Helical gears feature teeth that are cut at an angle, allowing them to engage gradually and more than one tooth at a time. This design results in smoother and quieter operation, making them superior for high-speed applications like automotive transmissions. The angled teeth also provide a larger contact area, granting them a higher load-carrying capacity compared to spur gears of the same size. A basic principle emphasized by the Society of Manufacturing Engineers (SME) is that the smoothness of gear engagement directly impacts the overall system’s vibration levels and operational lifespan.

3. Specialized Gears for Unique Transmission Challenges

Beyond these common types, specific applications demand specialized solutions. Bevel gears, with their conical shape, are designed to transmit power between intersecting shafts, typically at a 90-degree angle, as seen in differential drives. Worm gears offer very high reduction ratios in a compact space and possess a natural self-locking feature, which is invaluable for applications like hoists and lifts where back-driving must be prevented. Understanding these core types is the foundation for strategic selection.

How to Select the Right Gear for Extreme Operating Conditions?

Once the basic type is identified, selection must be refined against five key performance indicators (KPIs) to ensure survival in harsh environments.

- Analyzing Load Capacity and Operational Shock: The first KPI is load capacity, which must account not just for steady-state loads but also for peak and shock loads. In applications like mining crushers, the initial impact on the gears can be many times the normal operating load. Selecting a gear based solely on average load is a recipe for premature failure. The gear material and heat treatment must be chosen to absorb these shocks without deforming or fracturing.

- The Critical Role of Precision and Surface Finish: Gear precision grade, defined by standards like AGMA or ISO, dictates the accuracy of the tooth profile and spacing. Higher-precision gears ensure optimal meshing, which minimizes stress concentrations, reduces vibration, and enhances efficiency. In extreme conditions, a superior precision grade is not a luxury but a necessity for achieving reliable long-term performance and protecting the entire drivetrain. As detailed in the ASM international handbook, the relationship between material properties and manufacturing precision is paramount for durability under heavy loads.

- Controlling Wear, Vibration, and Thermal Stability: The final KPIs involve combating degradation. Abrasive and adhesive wear is mitigated through proper material selection and surface hardening. Vibration and noise control are indirect indicators of health; excessive levels signal misalignment or wear. Finally, thermal stability — the ability to maintain mechanical properties at elevated temperatures — is crucial for applications like steel rolling mills. A holistic view of these five KPIs guides the selection from a standard catalog part toward a more engineered solution.

What Advanced Materials and Engineering Principles Maximize Gear Lifespan?

Surviving extreme conditions requires leveraging advanced materials science and rigorous engineering principles that go beyond standard offerings.

1. Material Science: From Alloy Steels to Advanced Heat Treatment

The base material is typically an alloy steel chosen for its strength, toughness, and hardenability. However, the true performance is unlocked through heat treatment. Case-hardening processes like carburizing create a hard, wear-resistant surface layer while maintaining a tough, ductile core that can absorb shock loads. This is far superior to through-hardening for most heavy-duty applications. For engineers seeking a deeper understanding, a comprehensive guide to industrial gear materials and processes can provide a systematic framework for evaluation.

2. Precision Manufacturing for Optimal Tooth Geometry

The best material is ineffective if poorly manufactured. Precision grinding of the gear teeth after heat treatment is essential for achieving the required tooth profile, lead, and pitch accuracy. This process removes distortions from heat treatment and creates a superior surface finish, which minimizes friction, wear, and the risk of micro-pitting. Manufacturing under certifications like ISO 9001 and AS9100D ensures that these processes are controlled, repeatable, and traceable.

3. The Systems Approach: Integrating the Gear into the Whole

A gear does not operate in isolation. Its longevity is affected by the quality of the gearbox housing, the accuracy of shaft alignment, and the performance of the bearings. An engineering principle that maximizes lifespan considers the entire system, designing and manufacturing the gear as an integrated component rather than an isolated part. This holistic view is a hallmark of a mature reliability strategy.

Can a Proactive Maintenance Strategy Truly Prevent Costly Downtime?

Even a perfectly selected and manufactured gear will fail without proper care. Shifting from a reactive to a proactive maintenance culture is the final pillar of prevention.

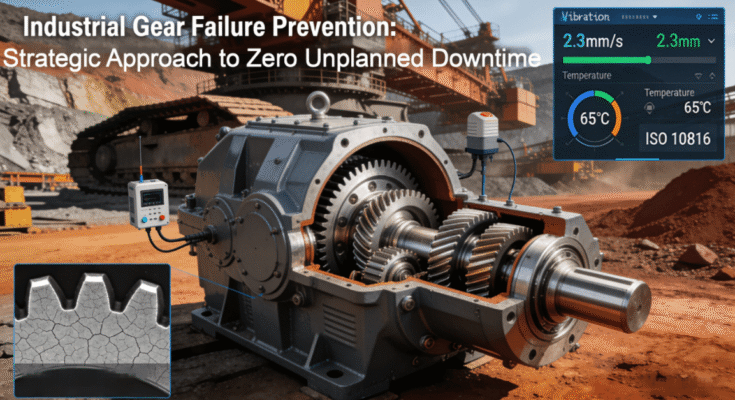

- Moving from Reactive to Predictive Maintenance: A proactive maintenance strategy aims to identify potential issues before they lead to failure. This replaces unpredictable downtime with scheduled, planned interventions. Techniques like regular vibration analysis can detect imbalances, misalignment, and bearing wear months before a catastrophic failure. Thermographic imaging can identify hot spots caused by excessive friction or inadequate lubrication.

- The Lifeline: Proper Lubrication Management: Lubrication is the lifeline of any gearbox. The correct lubricant does more than reduce friction; it carries away heat, protects against wear, and prevents corrosion. A disciplined lubrication management program — using the right type and viscosity of oil, maintaining cleanliness, and adhering to change intervals — is arguably the most cost-effective way to extend gear life exponentially.

- Quantifying the ROI of a Proactive Program: The return on investment is clear. For example, a mining company struggling with a gearbox failure every six months implemented a custom gearbox solution paired with a predictive maintenance program. This allowed them to extend service intervals to 24 months, achieving a 30% reduction in maintenance costs and eliminating the production losses from unplanned downtime. This case demonstrates that a proactive approach is not an expense but a strategic investment.

When Does a Standard Gear Fall Short, Demanding a Custom Solution?

There are clear limitations to what standard, catalog-sourced gears can achieve. Recognizing these boundaries is key to avoiding chronic reliability problems.

1. Limitations of Standard Geometries and Ratings

Standard gears are designed for common applications and may fall short when faced with unique challenges. These include severe space constraints, non-standard torque or speed requirements, the need for extreme reduction ratios, or operating environments with high levels of contamination or extreme temperatures. Using a standard gear in these situations often leads to a repetitive cycle of failure and downtime.

2. The Engineering Process Behind a Custom Solution

A custom engineering solution begins with a deep analysis of the application’s specific demands. Engineers model the loads, analyze the thermal environment, and select materials and heat treatments tailored to the stress cycles. The gear geometry is optimized using advanced software to ensure even load distribution and maximum efficiency. As demonstrated in successful gear machining services for challenging applications, this tailored approach resolves chronic failures that standard parts cannot.

3. Total Cost of Ownership: The True Measure of Value

While a custom gear may have a higher initial purchase price, its true value is measured by the total cost of ownership. A custom solution, by delivering dramatically extended service life and eliminating unplanned downtime, often proves far more economical over the asset’s life than the repeated cost and disruption of replacing inadequate standard parts.

Conclusion

The reliability of industrial gears is not merely a component selection issue but a comprehensive systems engineering approach. It encompasses the correct choice of gear type, precise selection based on key performance indicators, the application of advanced materials and manufacturing principles, and the implementation of a proactive maintenance strategy. Adopting this holistic methodology is the cornerstone for manufacturers aiming to achieve maximum operational efficiency and world-class asset reliability. By viewing gear drives as a critical, engineered system, unplanned downtime can be transformed from an inevitable cost into a manageable variable.

FAQs

Q1: What are the most common signs of impending gear failure?

A: The most common early warning signs include an unusual increase in vibration or noise, which often indicates misalignment, wear, or tooth damage. A sustained rise in operating temperature points to excessive friction from inadequate lubrication or overloading. A critical sign is an unexplained increase in energy consumption for the same output, signaling that the system is losing efficiency.

Q2: How does the precision grade of a gear impact overall system performance?

A: The precision grade directly dictates the accuracy of the tooth profile and spacing. Higher-precision gears ensure smoother meshing, which results in significantly lower vibration and noise, higher transmission efficiency, and reduced wear on the gears and supporting bearings. For high-performance applications, a superior grade is essential for reliability.

Q3: What is the difference between through-hardening and case-hardening for gears?

A: Through-hardening increases the hardness of the entire gear tooth, providing good overall strength but limited resistance to surface wear. Case-hardening processes, like carburizing, create a hard, wear-resistant surface layer while maintaining a tough, ductile core that can absorb shock loads, making it superior for high-stress applications.

Q4: Why might a custom-designed gear be more cost-effective than a standard catalog part?

A: While a custom gear may have a higher initial cost, it is engineered for the specific application demands. This optimization leads to a dramatically extended service life and a drastic reduction in unplanned downtime. When the total cost of ownership is calculated, the custom solution is often far more economical.

Q5: How important is lubrication selection for gearbox longevity?

A: Lubrication selection is critical. The correct lubricant forms a protective film to prevent metal-to-metal contact, carries away heat, and protects against corrosion. Using the wrong lubricant can lead to a rapid temperature increase, accelerated wear, and premature failure. Adhering to specifications is one of the most effective longevity strategies.