In the highly regulated food and beverage industry, maintaining product quality, safety, and consistency is paramount. Every stage of production, from raw ingredient handling to packaging, must comply with strict hygiene standards to protect consumer health and meet industry regulations. One of the most critical components in achieving this is hygienic flow meters — precision instruments designed to measure the flow of liquids, including water, milk, juices, beer, and syrups, while upholding the highest sanitary requirements.

This blog will explore what hygienic flow meters are, why they are essential in food and beverage processing, and the key benefits they offer to manufacturers striving for efficiency, accuracy, and compliance.

What Are Hygienic Flow Meters?

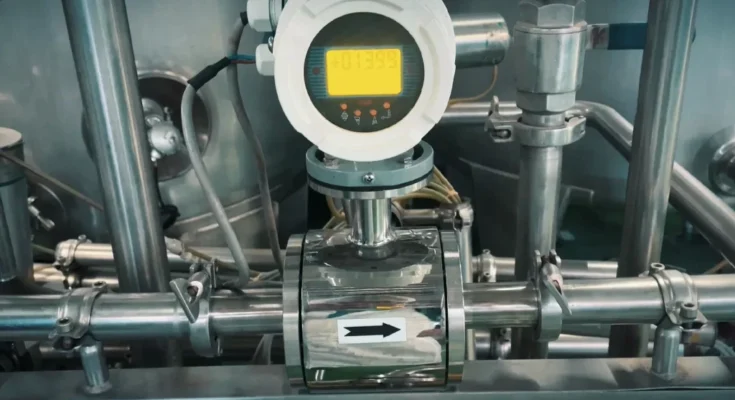

Hygienic flow meters are specially engineered to measure the flow rate of fluids in sanitary environments such as food, beverage, pharmaceutical, and biotechnology industries. Unlike standard industrial flow meters, hygienic flow meters are built with materials, designs, and surface finishes that prevent bacterial growth and facilitate easy cleaning.

These flow meters typically feature:

- Smooth, crevice-free surfaces

- Stainless steel construction (often 316L grade)

- CIP (Clean-in-Place) and SIP (Sterilize-in-Place) compatibility

- Sanitary process connections (like Tri-Clamp fittings)

The design ensures that no residues, contaminants, or microorganisms can accumulate within the meter, making it safe for applications where hygiene is non-negotiable.

Importance of Flow Measurement in Food and Beverage Processes

Accurate flow measurement is critical in food and beverage processing for several reasons:

- Batch Control: Precise dosing of ingredients is essential to maintain product consistency and taste.

- Quality Assurance: Consistent flow ensures that the final product meets strict quality specifications.

- Process Optimization: Real-time flow data helps in adjusting operations for maximum efficiency and minimal waste.

- Regulatory Compliance: Meeting hygiene standards and traceability requirements is mandatory in food production.

Hygienic flow meters directly contribute to these goals by providing reliable, contamination-free measurements that align with industry safety regulations.

Key Features of Hygienic Flow Meters

Hygienic flow meters are distinguished by several essential features designed for sanitary environments:

- Stainless Steel Construction: Provides corrosion resistance and meets food safety standards.

- Smooth Internal Surfaces: Prevents build-up of product residues and bacteria.

- Non-Invasive Designs: Some meters, like ultrasonic types, offer non-contact measurement, reducing contamination risks.

- CIP/SIP Capability: Can be cleaned and sterilized without disassembly, minimizing downtime.

- Sanitary Process Connections: Simplify installation and ensure leak-free, cleanable joints.

- Compliance with Industry Standards: Such as EHEDG (European Hygienic Engineering and Design Group), FDA, and 3-A Sanitary Standards.

These features make hygienic flow meters ideal for measuring everything from thin liquids like water to viscous products like syrups and dairy.

Types of Hygienic Flow Meters Used in Food and Beverage Industry

1. Electromagnetic Flow Meters

Electromagnetic flow meters, commonly known as mag meters, are widely used for conductive liquids like milk, juice, and beer. They provide accurate, obstruction-free measurement with no moving parts, making them easy to clean and maintain.

2. Coriolis Mass Flow Meters

Coriolis meters measure mass flow directly and are suitable for a wide range of fluids, including those with varying densities and viscosities. They offer excellent accuracy and are highly hygienic due to their smooth, self-draining designs.

3. Ultrasonic Flow Meters

Ultrasonic flow meters use sound waves to measure flow and can be either clamp-on or inline. They are non-invasive, which reduces the risk of contamination and are perfect for CIP processes.

4. Turbine Flow Meters

Turbine meters are sometimes used for low-viscosity fluids like water and light syrups. They provide reliable measurements but may require careful cleaning to ensure hygienic conditions.

Benefits of Hygienic Flow Meters in Food and Beverage Processes

1. Compliance with Sanitary Standards

Hygienic flow meters are specifically designed to meet food safety regulations. Their materials, construction, and cleanability ensure compliance with strict hygiene standards like those set by the FDA, EHEDG, and 3-A.

2. Accurate Flow Measurement

Precise flow measurement is vital for maintaining product quality and consistency. Hygienic flow meters deliver high levels of accuracy, allowing producers to maintain strict control over ingredient ratios, mixing, and filling processes.

3. Enhanced Product Quality

By providing reliable and repeatable flow data, hygienic flow meters help ensure that products like beverages, sauces, and dairy maintain consistent texture, flavor, and quality across batches.

4. Easy Cleaning and Maintenance

Flow meters designed for hygienic applications support CIP and SIP processes, allowing the system to be cleaned without disassembly. This reduces downtime and simplifies maintenance, improving overall productivity.

5. Minimized Risk of Contamination

The smooth, crevice-free design of hygienic flow meters minimizes areas where bacteria can hide. This design, combined with high-quality stainless steel construction, reduces the risk of contamination and spoilage.

6. Real-Time Process Control

Hygienic flow meters provide instant feedback on flow rates, enabling operators to make quick adjustments to keep processes within specification. This responsiveness improves yield and reduces waste.

7. Versatility Across Applications

These flow meters can handle a wide range of products — from thin beverages like water and juice to thicker fluids like syrups and creams. Their versatility makes them suitable for various stages of food and beverage processing.

8. Durability in Challenging Environments

Hygienic flow meters are built to withstand temperature fluctuations, frequent cleaning cycles, and exposure to chemicals commonly used in food processing plants, ensuring long-term reliability.

Typical Applications in the Food and Beverage Industry

Hygienic flow meters play a vital role in numerous food and beverage processes, including:

- Milk and Dairy Processing: Precise measurement of milk, cream, and yogurt in continuous and batch processes.

- Beverage Production: Flow monitoring in the production of juices, soft drinks, beer, and bottled water.

- Sauce and Syrup Manufacturing: Accurate flow control for viscous products to maintain consistency.

- Filling and Packaging Lines: Ensuring correct filling volumes for bottles, cartons, and pouches.

- CIP Systems: Monitoring cleaning fluid flow rates to ensure effective cleaning cycles.

In each of these applications, hygienic flow meters help maintain the highest levels of product integrity and safety.

Selecting the Right Hygienic Flow Meter

When choosing a hygienic flow meter for food and beverage applications, several factors must be considered:

- Fluid Type: Consider viscosity, temperature, and whether the fluid is conductive.

- Required Accuracy: High-precision processes may demand mass flow meters like Coriolis types.

- Cleaning Requirements: Ensure the meter supports CIP/SIP procedures.

- Installation Space: Assess whether an inline or clamp-on model best fits the system layout.

- Regulatory Compliance: Verify that the meter meets all relevant food safety standards.

Selecting the appropriate meter ensures accurate measurement, reliable operation, and easy integration with existing processes.

Conclusion

Hygienic flow meters are indispensable in the food and beverage industry, where accuracy, product safety, and regulatory compliance are top priorities. These specialized flow meters offer unmatched benefits, including precise flow measurement, easy cleaning, contamination prevention, and real-time data that supports optimized production.

From dairy to beverage bottling, hygienic flow meters contribute to the consistent delivery of high-quality products while helping manufacturers meet the stringent standards required in today’s market.

Investing in the right hygienic flow measurement solution not only improves operational efficiency but also strengthens consumer trust by ensuring safe and reliable food production processes.